Several challenges, technical and otherwise, must be overcome before fuel cell vehicles (FCVs) will be a successful, competitive alternative for consumers.

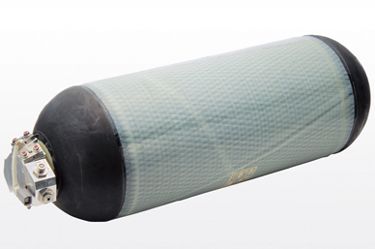

Onboard Hydrogen Storage

Some FCVs store enough hydrogen to travel as far as gasoline vehicles between fill-ups—about 300 miles—but the storage systems are still too large, heavy, and expensive. more...

FCVs are more efficient than conventional cars, and hydrogen contains three times more energy per weight than gasoline does. However, hydrogen gas contains only a third of the energy per volume gasoline does, making it difficult to store enough hydrogen to go as far as a gasoline vehicle on a full tank—at least within size, weight, and cost constraints.

Hydrogen can be stored in three basic ways:

-

As a gas in high-pressure tanks. Current FCV designs use high-pressure (5,000- to 10,000-psi) tanks to store hydrogen. These systems are large, heavy, and costly, but they are the most cost-effective solution in the near term.

-

As a liquid at sub-zero temperatures (-423°F). Since hydrogen is densest as a liquid, this method allows more hydrogen storage than gaseous high-pressure storage but costs 30 times more and suffers from safety and performance issues. Liquid storage isn't likely to be commercially viable for more than a decade.

-

Materials-based storage. Hydrogen can be stored inside solid materials through absorption, adsorption, and chemical reactions. Materials-based systems have the potential to be small and lightweight and may prove to be the best solution in the long term. However, they are still in the early stages of development.

Click here for more about hydrogen storage from EERE's Fuel Cell Technologies Program.

Vehicle Cost

FCVs are currently too expensive to compete with hybrids and conventional gasoline and diesel vehicles. Manufacturers must bring down production costs, especially the costs of the fuel cell stack and hydrogen storage. more...

Source: USDOE, Hydrogen Program: Program Records 5005, 8002, 8019, and 9012.

Fuel cell system costs have decreased significantly over the past several years but are still nearly twice as high as those for internal combustion engines.

Likewise, onboard hydrogen storage costs are currently $15–$18/kWh for high-pressure gaseous storage, while the commercialization target is $2/kWh. There is potential to reduce this cost using lower-cost carbon fiber tanks or materials-based storage technologies, such as metal hydrides.

Fuel Cell Durability and Reliability

Fuel cell systems are not yet as durable as internal combustion engines and do not perform as well in extreme environments, such as in sub-freezing temperatures. more...

USDOE. 2009. Hydrogen and Fuel Cell Activities, Progress, and Plans: Report to Congress![]() , p. 19-20.

, p. 19-20.

Fuel cell stack durability in real-world environments is currently about one third of what is needed for commercialization. Durability has increased substantially over the past few years from 29,000 miles to 57,000 miles, but experts believe a 150,000-mile expected lifetime is necessary for FCVs to compete with gasoline vehicles.

Cold-weather operation can also be problematic since fuel cell systems always contain water, which can freeze at low temperatures, and must reach a certain temperature to attain full performance. FCVs can now start and operate in sub-freezing temperatures, but there are still some performance concerns.

Finally, contaminants can degrade fuel cell performance and durability, so it is unclear what level of purity of hydrogen and intake air will be required for FCVs to operate reliably in real-world conditions.

Getting Hydrogen to Consumers

The extensive system used to deliver gasoline from refineries to local filling stations cannot be used for hydrogen. New facilities and systems must be constructed for producing, transporting, and dispensing hydrogen to consumers.

Competition with Other Technologies

Manufacturers are still improving the efficiency of gasoline- and diesel-powered engines, hybrids are gaining popularity, and advances in battery technology are making plug-in hybrids and electric vehicles more attractive. FCVs will have to offer consumers a viable alternative, especially in terms of performance, durability, and cost, to survive in this ultra-competitive market.

Safety

Hydrogen, like any fuel, has safety risks and must be handled with caution. We are familiar with gasoline, but handling compressed hydrogen will be new to most of us. Therefore, developers must optimize new fuel storage and delivery systems for safe everyday use, and consumers must become familiar with hydrogen's properties and risks.

Public Acceptance

Finally, fuel cell technology must be embraced by consumers before its benefits can be realized. Consumers may have concerns about the dependability and safety of these vehicles, just as they did with hybrids.