| * |

|

Magnetic Nanostructures for Post-Complementary Metal-Oxide-Semiconductor (CMOS) Electronics

Summary:Just as integrated electronic circuits continue to pack on more and ever tinier components, so magnetic technologies for data storage and other applications grow ever denser, increasing their capacity by squeezing more bits and more sensors into smaller areas. Without innovations in materials, design, measurement, and manufacturing at the nanoscale, however, the miniaturization trend in magnetic technology would stall. Avoiding this impasse will require methods to build patterned arrays of nanoscale magnetic devices and recording media with patterned nanomagnets. This project aims to develop capabilities to measure and thereby potentially control damaging defects in magnetic nanostructures, including variations in the geometry, composition, and edge thickness of features that impact device performance. Description:

Tiny defects that cause no problems in larger structures pose a significant barrier to the development and commercialization of magnetic nanotechnologies. Yet, it is nearly impossible to fabricate nanostructures without occasional defects, such as irregularities in structure or shape. Thin films acquire some defects as a result of slight variations in the deposition process by which they are made. Etching patterns into the films creates additional defects, usually at the edges.

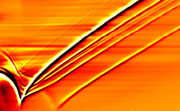

Promising data-storage technologies are especially vulnerable to defect-caused problems. One example is high-capacity magnetoresistive random access memory (MRAM), a permanent, or non-volatile, type of computer memory that can be accessed quickly. Other examples include recording media composed of patterned bits—identical, uniformly spaced nanoscale cells or particles, rather than the randomly oriented, contiguous magnetic grains that characterize the media in today’s computer hard disk drives. To perform reliably, all the nanostructured components in such devices must perform exactly the same way. For example, each nanomagnet in an array of billions in a bit-patterned disk must switch—or flip its magnetic orientation—in response to magnetic fields of identical strength. Even slight variations can cause errors when writing and reading information. Today, variations in switching behavior can be detected over relatively large areas, but current methods do not provide direct clues as to what causes different nanomagnets to flip their orientation in response to different applied magnetic fields. The goal of this project is to develop the measurement knowledge and the basic measurement tools for detecting, quantifying, and controlling nanoscale defects that underlie switching irregularities within arrays of nanodevices. Achieving that goal requires efforts on several fronts. We are using high-resolution magnetometry, microwave spectroscopy, and other methods to uncover the dominant types of defects and to develop in-situ measurements of magnetic properties to gauge the significance of those defects. In addition, we are developing measurements of vibrational modes, polarization, saturation, and other magnetic properties of nanoscale particles and film edges. As the size of these structures shrinks even further, they will become almost one dimensional. Measuring the magnetic properties of these “all edge” nanostructures will require these new techniques. Ultimately, this project aims to enable new magnetic electronic devices by determining how nanoscale defects disturb the magnetization behavior of nanostructures, individually and collectively. The results will help extend our understanding of the physics of nanomagnetic systems consisting of a few million atoms—too small to be studied with statistical and other methods for interpreting the bulk properties of materials. Data and findings also will be used to develop techniques to model, simulate, and predict the behavior and properties of magnetic nanostructures. Collectively, these techniques will be akin to the Object Oriented MicroMagnetic Framework programs and tools developed by NIST and collaborators. We anticipate that the project's scientific results will provide a foundation for measurements and analytical tools that will enable industry to efficiently develop and manufacture uniform nanomagnet arrays for future disk drive and MRAM products, as well as other next-generation technologies. Our results will also foster innovations in nanomagnetism applications and in processes for fabricating magnetic devices and arrays, including defect-tolerant magnetic component designs, optimized treatments of thin-film edges, and production-line diagnostic tools.

Selected Publications

|

Lead Organizational Unit:mmlCustomers/Contributors/Collaborators:National Institute of Standards and Technology Facilities/Tools Used:Staff:Bob McMichael - NIST Contact

June Lau, Phone 301-975-5711 or NIST |