| * |

|

Nanocalorimetry Measurements

Summary:To develop nanocalorimetry as a method for measuring heats of reaction of nanoscale samples with nanojoule sensitivity in order to detect reactions and quantify reaction thermodynamics and kinetics in multilayer structures. Particular interfaces of interest include those in multilayer advanced gate stacks for microelectronic devices. Description:

Accurate thermodynamic measurements are essential to understand fundamental properties of materials, providing direct and uantifiable insight into the thermodynamics of thin film reactions and phase transitions. Going forward, new classes of materials may only be synthesized as thin films, a scale at which traditional calorimetric techniques are not useful. The specific heat and other thermodynamic properties of small (nanogram) samples can be quantified, including, but not limited to, ultrathin and multilayered films, polymer coatings, biomaterials, and nanocrystalline and amorphous materials.

A variety of devices have recently been developed for nanocalorimetry, ranging from MEMS based differential scanning calorimeters (DSC) to scanning probe calorimeters. The ongoing development of these new devices requires advances in thermometry, and detailed understanding of the thermal behavior of the materials from which they are made. Discrete sensors for use at modest temperatures are commercially available; extending nanocalorimetry to higher temperatures is important for inclusion of more classes of materials. Our goal is to establish nanocalorimetry as a quantitative technique by developing MEMS-based nanocalorimeter sensors and instrumentation, calibration procedures, and reference materials for these devices. We will perform extensive thermal modeling of our nanocalorimeters in order to quantify the accuracy and precision of data generated by these devices. The applicability of nanocalorimetry will be demonstrated with measurements on industrially relevant materials, such as multilayer thin film structures necessary for next generation integrated circuit devices. Impact and Customers:

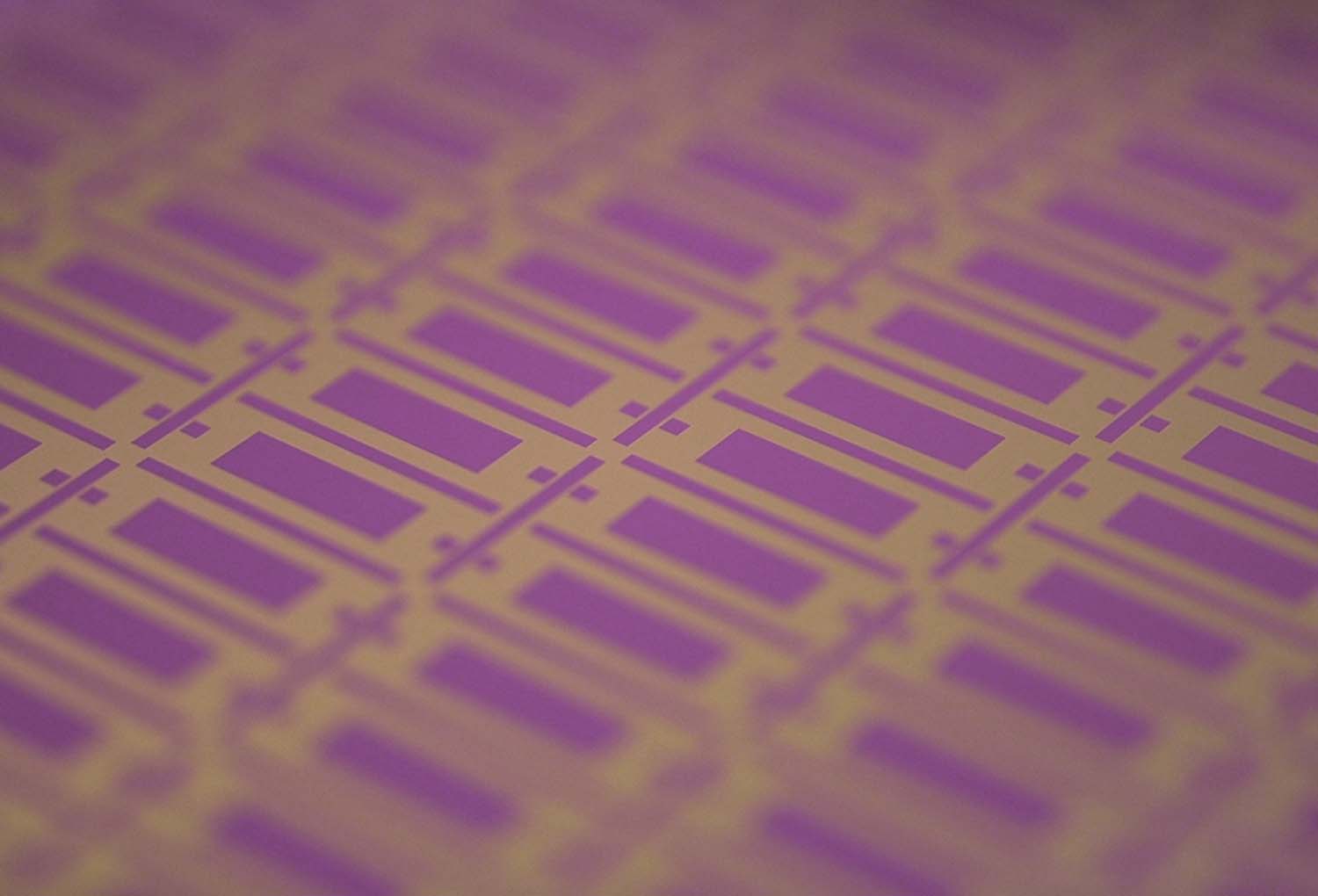

Major Accomplishments:We are investigating MEMS nanocalorimeters for use in characterizing nanoscale inorganic thin films and biological materials. Based on our characterization of current nanocalorimeterrs, we are designing new types of nanocalorimeters, and will manufacture these new devices in the state-of-the-art NIST Nanofab. Detailed modeling is being employed to guide the characterization and design, based on a non-linear, 3-D, parametric, fully coupled thermal-electrical-mechanical finite element model and numerical design optimization.  Nanocalorimeter data showing a sharp melting peak achieved from a 50 nm thin film of pure aluminum. The sample mass is ˜400 ng Another goal of our program is to make thermodynamic measurements on combinatorial materials libraries deposited onto dense arrays of smaller sized nanocalorimeters. Recent measurements were performed on a multilayer thin film system that is of great importance to the silicon microelectronics industry (as a source/drain contact metallization), nickel silicide. Separate Ni and Si thin films were deposited on the nanocalorimeter, and reacted to form nickel silicide during the first heating cycle. The reaction went to completion, as additional heating cycles showed no further reaction taking place. Since the devices have very small thermal mass, they can be ramped,in high vacuum, at rates as fast as 50,000 °C/s; such high rates may be necessary to adiabatically capture the thermal signature of such reactions.  Nanocalorimeter data showing the reaction between nanometer scaled silicon and nickel thin films to form nickel silicide. Existing devices are currently limited by a number of factors that this project aims to address. First, the devices themselves are not stable at temperatures much above 700°C; redesigning the chip for operation at higher temperature would greatly expand the types of experiments and classes of materials that may be studied. Secondly, the control instrumentation is currently based on open-loop algorithms, so the heating and cooling rates vary throughout each experiment depending on the instantaneous heat losses, as well as the sample properties and/or a sample reaction. Establishing feedback controlled instrumentation should provide for greater accuracy in the thermodynamic measurements. The new control system will rely on a state-of-the-art 24-bit data acquisition system, which should reduce the digitization error (and associated noise introduced into numerical derivatives) by two orders of magnitude. Calibration of the nanocalorimeter devices is currently time consuming and error prone. Current nanocalorimeter measuremets have a temperature uncertainty on the order of 10 %. Implementing a new calibration scheme should allow the calibration to be performed over a very broad temperature range, with temperature uncertainty reduced to below ±3 °C, which is less than 1 % of the measurement. Future applications will be in the area of biological materials. For example, the purely structural analysis of the interaction of ligands with nucleic acids and proteins has not produced a fruitful stream of drug candidates as once was imagined; it is difficult to predict binding kinetics based on “good” structural candidates. Accurate measurements of the thermodynamic properties of molecular interactions from small biological samples are needed to speed the evaluation of interaction between/among biomolecules, and to develop a deeper understanding of the energetics of biological recognition, binding and fusion events.  The infection process of a paramyxovirus is a three step process – binding of viral proteins to receptors, activation of fusion proteins and thenfusion of the viral membrane with the cell lipid bilayer. Nanocalorimeters may be able to quantify the energetics of such biological processes.

|

Start Date:October 28, 2008End Date:ongoingLead Organizational Unit:mmlStaff:Associated Products:Project Summary (PDF) Contact

David LaVan

|

Advanced electronic and optoelectronicmaterials are used in highly integrated structures such as multilayer thin film stacks. The performance of devices containing such structures is critically dependent on the stability of the thin film interfaces. Nanocalorimetry can determine the stability of multilayer thin film structures by quantifying the thermodynamics of interfacial reactions.

Advanced electronic and optoelectronicmaterials are used in highly integrated structures such as multilayer thin film stacks. The performance of devices containing such structures is critically dependent on the stability of the thin film interfaces. Nanocalorimetry can determine the stability of multilayer thin film structures by quantifying the thermodynamics of interfacial reactions.