| * |

|

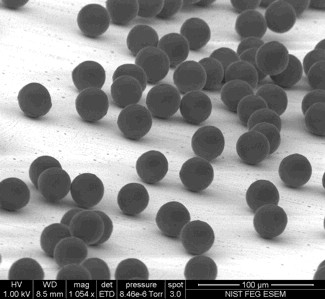

Polymer Microspheres by Co-Flow Extrusion for Homeland Security

Summary:Well characterized test materials are essential for validating the performance of trace explosive detection systems. Particle size, chemical composition, and detector response are particularly important. This year we have developed a new method for making explosive particulate standard materials. We are producing monodisperse polymer microspheres encapsulating explosives and explosive simulants via a sonicated annular co-flow nozzle. Polymer microspheres are an attractive delivery platform for the testing of trace explosive detection instruments for several reasons: real-world explosive contamination typically comes in the form of micrometer sized particles, both particle size and composition can be tailored, and the polymer matrix may extend the lifetime of more-volatile analytes. Description:We are making prototype test particles that contain explosives and simulants to be used to verify analyst’s procedures and instrumentation used for trace analysis. The process uses a sonicated annular co-flow device that delivers precisely controlled liquid droplets into water where they undergo an oil/water emulsion process and eventually cure into hardened microspheres. The polymer is dissolved in dichloromethane (DCM) with a known amount of the analyte (explosive or simulant) added to the solution. The PLGA/analyte solution is forced via syringe pump through a 22-gauge hypodermic needle at flow rates from 1-10 mL/h. An annular co-flow stream of water containing polyvinyl alcohol (PVA) surfactant flows annularly around the emerging PLGA stream at flow rates from 60-90 mL/h. The confluence of both streams is forced through a small orifice (~ 200 µm in diameter) at the tip of the glass capillary tube. The entire nozzle assembly is attached to the tip of a sonic probe controlled by a frequency generator. The applied frequency of the transducer generates periodic instabilities in the jet which breaks the stream of PLGA into uniform liquid droplets. Droplet size can be controlled to produce final microsphere diameters range from about 5 micrometers to about 90 micrometers in diameter, depending on the operating parameters. The jetting process takes place under water where the microspheres are collected and cured in a 2 L beaker containing low concentrations of surfactant. Stroboscopic videography allows us to image the jetting process in real-time The water and polymer phases are immiscible leading to the formation of an emulsion. The surfactant is used for emulsion stabilization and is shown to be an excellent stabilizer for polymer spheres prepared by emulsification methods. The microspheres are continuously stirred for several hours to evaporate all residual DCM. The microspheres can then be harvested after suitable cleaning, filtration, and drying. Major Accomplishments:Successfully incorporated the high explosives RDX, PETN, HMX, and TNT. Monodisperse particle size distributions with coefficients of variance less than 3%. High particle production rates; tens of millions of microspheres per hour |

Start Date:October 29, 2008End Date:ongoingLead Organizational Unit:mmlFacilities/Tools Used:Advanced Measurement Laboratory Precision Particle Fabrication Facility Associated Products:NIST Report of Analysis 837-41-08: Production of Polymer Microspheres Containing Trace Explosives Using Precision Particle Fabrication Technology Contact

Matthew Staymates |