Benefits

Less Greenhouse Gas Emissions

Gasoline- and diesel-powered vehicles emit greenhouse gases (GHGs), mostly carbon dioxide (CO2), that contribute to global climate change. Fuel cell vehicles (FCVs) powered by pure hydrogen emit no GHGs from their tailpipe, only heat and water.

Producing the hydrogen to power FCVs can generate GHGs, depending on the production method, but much less than that emitted by conventional gasoline and diesel vehicles. more...

The chart below shows the GHGs generated by various vehicle types and considers all steps of the energy chain from fuel extraction or production to use by the vehicle, not just tailpipe emissions. Even when accounting for the GHGs emitted during hydrogen production, conventional gasoline vehicles generate roughly 2 to 10 times more GHGs per mile than FCVs.

Well-to-Wheels Greenhouse Gases Emissions for Future Mid-Size Car, 2035–2045

(grams of CO2-equivalent per mile)

U.S. Department of Energy. 2010. Well-to-Wheels Greenhouse Gas Emissions and Petroleum Use for Mid-Size Light Duty Vehicles.![]() Hydrogen Program Record #10001.

Hydrogen Program Record #10001.

Less Air Pollutants

Highway vehicles emit a significant share of the air pollutants that contribute to smog and harmful particulates in the U.S. FCVs powered by pure hydrogen emit no harmful pollutants. If the hydrogen is produced from fossil fuels, some pollutants are produced, but much less than the amount generated by conventional vehicle tailpipe emissions.

Reduced Oil Dependence

FCVs could reduce our dependence on foreign oil since hydrogen can be derived from domestic sources, such as natural gas and coal, as well as renewable resources such as water. That would make our economy less dependent on other countries and less vulnerable to oil price shocks from an increasingly volatile oil market.

Challenges

Several challenges must be overcome before fuel cell vehicles (FCVs) will be a successful, competitive alternative for consumers.

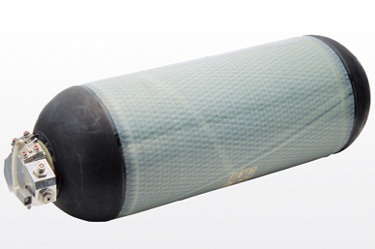

Onboard Hydrogen Storage

Some FCVs store enough hydrogen to travel as far as gasoline vehicles between fill-ups—about 300 miles—but this must be achievable across different vehicle makes and models and without compromising customer expectations of space, performance, safety, or cost. more...

FCVs are more energy efficient than conventional cars, and hydrogen contains three times more energy per weight than gasoline does. However, hydrogen gas contains only a third of the energy per volume gasoline does, making it difficult to store enough hydrogen to go as far as a gasoline vehicle on a full tank—at least within size, weight, and cost constraints.

The following storage methods are being explored:

As a gas in high-pressure tanks. Current FCV designs use high-pressure (5,000- to 10,000-psi) tanks to store hydrogen. These systems are large, heavy, and costly, but they are the most cost-effective solution in the near term.

As a liquid at sub-zero temperatures (-423°F). Since hydrogen is densest as a liquid, this method allows more hydrogen storage than gaseous high-pressure storage. Issues with liquid storage include hydrogen boil-off, the energy required for hydrogen liquefaction, volume, weight, and tank cost.

Materials-based storage. Hydrogen can be stored inside solid materials through absorption, adsorption, and chemical reactions. Materials-based systems have the potential to be small and lightweight and may prove to be the best solution in the long term. However, they are still in the early stages of development.

Click here for more about hydrogen storage from EERE's Fuel Cell Technologies Program.

Vehicle Cost

FCVs are currently more expensive than conventional vehicles and hybrids. Manufacturers must bring down production costs, especially the costs of the fuel cell stack and hydrogen storage, to compete with conventional technologies. more...

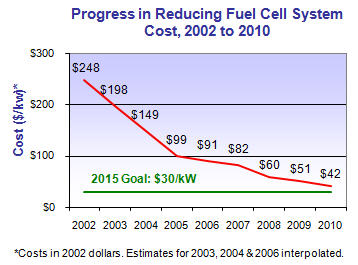

Source: USDOE, Hydrogen Program: Program Records 5005, 8002, 8019, 9012, and 10004.

Fuel cell system costs have decreased significantly over the past several years and are nearing DOE's cost goal for 2015.

Onboard hydrogen storage cost targets are currently being re-assessed by DOE.

Fuel Cell Durability and Reliability

Fuel cell systems are not yet as durable as internal combustion engines, especially in some temperature and humidity ranges. more...

USDOE. 2009. Hydrogen and Fuel Cell Activities, Progress, and Plans: Report to Congress![]() , p. 19-20.

, p. 19-20.

USDOE. Progress and Accomplishments in Hydrogen and Fuel Cells.

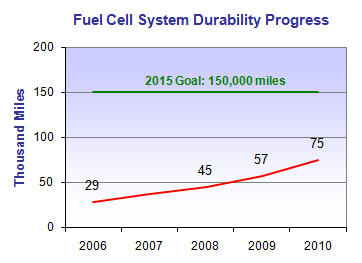

Fuel cell stack durability in real-world environments is currently about half of what is needed for commercialization. Durability has increased substantially over the past few years from 29,000 miles to 75,000 miles, but experts believe a 150,000-mile expected lifetime is necessary for FCVs to compete with gasoline vehicles.

Getting Hydrogen to Consumers

The extensive system used to deliver gasoline from refineries to local filling stations cannot be used for hydrogen. New facilities and systems must be constructed for producing, transporting, and dispensing hydrogen to consumers.

Public Acceptance

Finally, fuel cell technology must be embraced by consumers before its benefits can be realized. Consumers may have concerns about the dependability and safety of these vehicles, just as they did with hybrids.