Plasma technology for textile finishing applications gets a boost from LANL

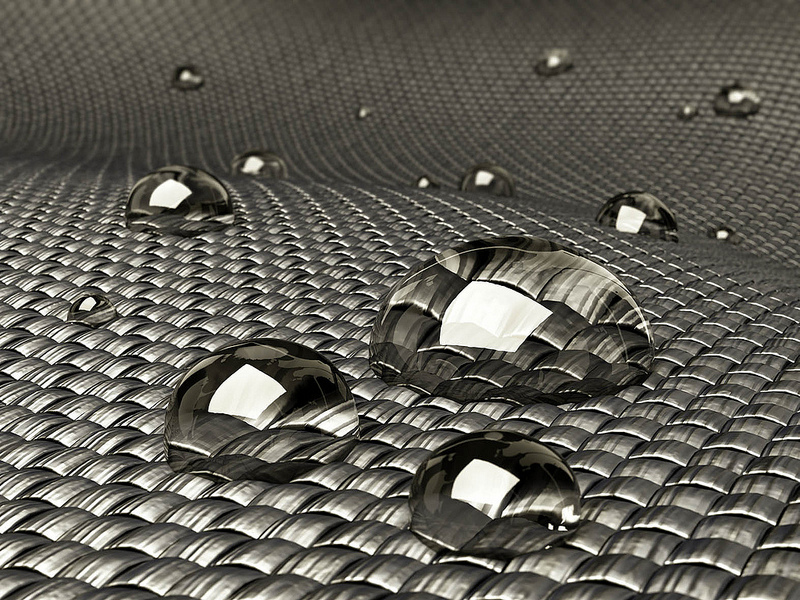

Gary Selwyn conducts product quality assurance on dual-functional, plasma-treated fabric at APJeT's Santa Fe lab: LANL technology may transform performance apparel

Contact

- CEO

- John Emrich

- (505) 471-6399

A new way to stay dry: APJeT is revolutionizing the textile industry with new plasma technology

Gary Selwyn first used plasma technology for textile finishing applications while employed at Los Alamos National Laboratory. Today, as Chairman and Chief Technology Officer of Affiliated Plasma Jet Technologies, Inc. (APJeT), a privately held small company based in Santa Fe, New Mexico, he is revolutionizing the textile industry.

APJeT executed an exclusive license in 2002 for all fields of use involving the Atmospheric Pressure Plasma Jet (APPJ®)technology. The licensed APPJ technology is a broad-based, platform technology consisting of several different apparatus and methods patents on the use of different applications and designs of plasma sources for generating and using a low temperature, highly reactive plasma for materials processing applications.

The most advanced application of APJeT’s technology is for treating fabric with atmospheric-pressure plasma so that it becomes “dual-functional,” repelling oil and water on the outside, while retaining its original qualities and comfort on the inside. This is ideal for outdoor sports apparel, APJeT’s targetmarket.

APJeT uses its proprietary atmospheric pressure plasma technology to apply to fibers a nanometer-thin polymeric film that enables fabric to repel water and stains without changing its feel or appearance. By combining electrical power with a selected gas, the ionization process that occurs in the plasma produces active, gas-phase chemicals that bond to the surface of the fabric, producing unique properties.

"We use atmospheric plasma to chemically modify textiles, such as polyester, to make them wick water better than cotton by bonding atomic oxygen to the surface," he said. "It breathes well, feels great against the body, and with a different plasma, we make the outer surface rain resistant, all properties essential for outdoor performance clothing."

APJeT's dual-functional finish, trade named AP-TeX®, is about to go to market.

And unlike traditional wet processing of fabrics, the plasma process is green in that it produces no waste and uses little energy. After launching, APJeT received a $100,000 Venture AccelerationFund award from LANS. The funding helped complete the design and engineering of a commercial-scale production unit.

For APJeT, the full-scale prototype attracted new private equity financing and two strategic partnerships: one with a productionand equipment services company, and another with North Carolina State College of Textiles, which provides APJeT with a showcase and limited testing facility.

APJeT stands for “Affiliated Plasma Jet Technologies,”indicating an intention to spin off other affiliates in the near future.

Today, APJeT is expanding its production capacity in North Carolina and making plans to spin off their current work in textiles.