Increased durability and lifetime of fuel cell products

The LANL method for manufacturing a durable fuel cell MEA offers significant cost reductions and performance enhancements necessary for mainstream applications.

Contact

- Marcus A. Lucero

- Technology Transfer

- (505) 665-6569

Increased durability and lifetime of fuel cell products

Applications:

- Membrane electrode assembly process

- Catalyst adhesion

- Membrane production preparation

- Perfluorinated sulfonic acid (NafionTM) and hydrocarbon- based MEAs

- Sensors and/or electrochemical devices

Benefits:

- Significant improvement in durability over industrial MEAs

- Improves interfacial and mechanical bond between catalyst and membrane

- Reduces electricity costs related to heating and cooling MEA

- Eliminates need for an MEA conditioning/hydrating step after bonding

- Requires lower temperature bonding conditions, thus lower cost production equipment

Summary:

Conventional polymer electrolyte membrane (PEM) fuel cell technology, at the forefront of research into cleaner and greener power and energy solutions, suffers from a lack of durability, high manufacturing costs, and rapid performance degradation. These factors overshadow the technology’s potential benefits and have prevented fuel cells from entering the mainstream automobile, portable electronics, and power generation markets in which customers are price sensitive and selective in their purchases of durable goods.

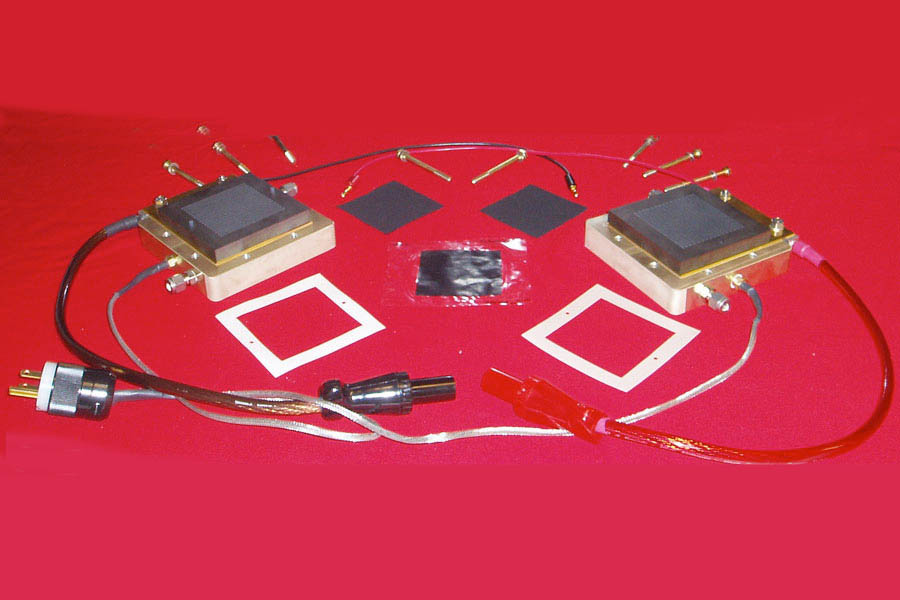

A revolutionary method of building a membrane electrode assembly (MEA) for PEM fuel cells has been developed by Los Alamos National Laboratory (LANL) scientists that can significantly increase durability, reduce manufacturing costs, and extend the lifetime of a fuel cell product. This method incorporates a unique polymer dispersion that can beappliedtobothperfluorinatedsulfonicacid(PFSA)andhydrocarbon-basedMEAsto produce superior electrode performance, stability, and durability during harsh fuel cell operating conditions.

The LANL-produced MEA has been evaluated and certified using an Accelerated Stress Test (AST) developed by the U.S. Department of Energy (DOE) in conjunction with car manufacturers. The AST was developed to study the durability of state-of-the-art MEAs and includes challenging performance targets (e.g., voltage losses of 0.8 A/cm2 less than 30 mV after potential cycling from 0.6 to 1.0 V for 30,000 cycles at 80°C). When comparing the results of the AST from a premier manufacturer’s commercially available MEA versus LANL’s novel MEA, the commercially available MEA did not meet the target after 30,000 cycles. However, voltage loss of LANL’s MEA still remained below 30 mV even after 70,000 cycles (see figure). Although the graphs are not shown, results obtained from two other commercially available PFSA dispersions also fell short of the DOE’s target with 48 and 33 mV losses after 30,000 cycles. In addition to this unique polymer dispersion method, the LANL MEA fabrication process utilizes a novel swelling agent that signifi- cantly lowers hot pressing temperatures and improves the interfacial stability of the MEA.

The MEA is an essential, yet highly expensive component of any PEM fuel cell. The LANL method for manufacturing a durable fuel cell MEA offers significant cost reductions and performance enhancements necessary for mainstream applications.

Development stage: Working prototype

Patent status: Patent pending

Licensing status: Los Alamos is seeking partners interested in joint collaborations and/or exclusive or non-exclusive licensing opportunities.