Tech Beat - October 16, 2012

|

In This Issue...

Editor: Michael Baum |

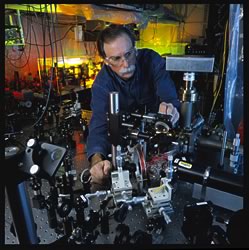

NIST Researcher David Wineland Wins 2012 Nobel Prize in PhysicsDavid J. Wineland, a physicist at the U.S. Department of Commerce’s National Institute of Standards and Technology (NIST), has won the 2012 Nobel Prize in Physics. The honor is NIST’s fourth Nobel prize in physics in the past 15 years.

Wineland shared the prize with Serge Haroche of the Collège de France and Ecole Normale Supérieure in Paris, France. In announcing the winners today, the Royal Swedish Academy of Sciences cited Wineland and Haroche "for groundbreaking experimental methods that enable measuring and manipulation of individual quantum systems." The Nobel citation notes that Wineland and Haroche’s methods have enabled science to take “the very first steps towards building a new type of superfast computer based on quantum physics. Perhaps the quantum computer will change our everyday lives in this century in the same radical way as the classical computer did in the last century. The research has also led to the construction of extremely precise clocks that could become the future basis for a new standard of time, with more than hundred-fold greater precision than present-day cesium clocks.” “We’re so excited for Dave, along with his many colleagues and friends around the world, for this recognition of decades of world-leading research,” said Under Secretary of Commerce for Standards and Technology and NIST Director Patrick Gallagher. “Dave’s work embodies NIST’s mission to pioneer new measurement science that will substantially advance technology and innovation.” Wineland has worked at NIST for 37 years and is internationally recognized for his research on trapped ions, which are electrically charged atoms. He conducted landmark experiments on laser cooling, which involves the use of lasers to cool ions to near absolute zero. This led to the development of laser-cooled atomic clocks, the current state-of-the-art clock in time and frequency standards; advances in experimental quantum computing, which use the rules of quantum physics to potentially solve important problems such as breaking the best data encryption codes, which are intractable using today's technology; and ultraprecise next-generation atomic clocks based on single ions. Wineland achieved the first demonstration of laser cooling in 1978 and has built on that breakthrough with many experiments that represent the first or best in the world—often both—in using trapped laser-cooled ions to test theories in quantum physics and demonstrate crucial applications. Wineland was the first to successfully demonstrate the building blocks of a practical quantum computer. In 2004, his was one of the first two research efforts (simultaneously with a group in Innsbruck) to demonstrate quantum teleportation of information among massive particles, providing a potentially crucial method for efficient transfer of information within a large-scale quantum computer. In 2005, he demonstrated the first “quantum logic atomic clock”, which is now the world’s most precise atomic clock and would neither gain nor lose one second in about 4 billion years. For more, see the Oct. 9, 2012, NIST news announcement, “NIST's David J. Wineland Wins 2012 Nobel Prize in Physics” at /www.nist.gov/public_affairs/releases/wineland-nobel-release.cfm. Media Contact: Laura Ost, laura.ost@nist.gov, 303-497-4880

New Reference Material to Help Get the Lead Out of Paints for Children's ProductsTo help manufacturers adhere to new regulations intended to reduce the risk of lead poisoning in children, researchers at the National Institute of Standards and Technology (NIST) have developed standard test samples of lead paint films of the sort sometimes found on children's products, as well as a guide* to their use. Manufacturers can use the new test—or "reference"—materials to demonstrate that their test methods yield accurate results when used to show compliance of products with the Consumer Product Safety Improvement Act (CSPIA) of 2008. The law requires that paints used on children's products contain no more than 90 milligrams of lead per kilogram of paint, a marked decrease from the prior standard, which allowed up to 600 mg/kg. It is enforced by the U.S. Consumer Product Safety Commission (CPSC). Lead is a powerful toxin that can cause harm to nearly every system of the body. According to the Centers for Disease Control and Prevention, about 250,000 U.S. children have blood levels of lead in excess of 10 micrograms per deciliter, the point at which they recommend treatment. Lead compounds were once widely used as pigments and durability agents in nearly all paint formulations. The use of lead ingredients is in decline as more alternatives become available and more regulations are brought to bear on the issue; however, lead can still occasionally be found in children's products. The CSPIA requires that results be reported in terms of total mass per kilogram instead of by unit area, i.e., micrograms per square centimeter, which the industry presently measures directly using handheld X-ray fluorescence instruments. Although the CPSC will not accept the results these instruments give as evidence of compliance, manufacturers will likely continue to use the method for fast screening and do more thorough checks if the results rise above a certain level. Manufacturers can prove compliance using a standard test method developed by ASTM International (ASTM F2853) that calls for the use of multiple X-ray beams with different energies to determine accurately the mass of lead per kilogram of paint. NIST researchers designed new Standard Reference Material (SRM) 2569 so it gives equally valid results when used with either of these measurement technologies. The reference material consists of polyester panels with one of three different paint compositions: one with no lead, one containing lead at 85 mg/kg, and one at 314 mg/kg. The paints on the panels have assigned values for paint thickness and density as well, which can be used to validate results, although they are not intended to be used as calibration standards or routine control materials for the instruments. This SRM joins a suite of NIST SRMs offered in support of measurements of lead in consumer products and buildings and their surroundings. For more information and to purchase, see SRM 2569 - Lead Paint Films for Children's Products at https://www-s.nist.gov/srmors/view_detail.cfm?srm=2569. Standard reference materials are among the most widely distributed and used products from NIST. The agency prepares, analyzes and distributes about 1,300 different materials that are used throughout the world to check the accuracy of instruments, validate test procedures and serve as the basis for quality assurance worldwide. * J.R. Sieber and J.L. Molloy, A guide to using SRM 2569 to validate analytical methods.Media Contact: Mark Esser, mark.esser@nist.gov, 301-975-8735

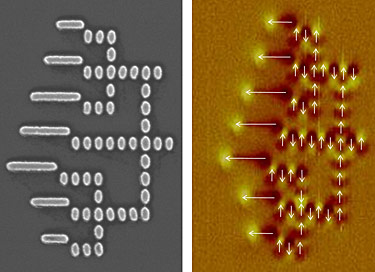

NRI to Lead New Five-Year Effort to Develop Post-CMOS ElectronicsThe National Institute of Standards and Technology (NIST) announced today the selection of the Nanoelectronics Research Initiative (NRI), a collaboration of several key firms in the semiconductor industry, to support university-centered research for the development of after-the-next-generation “nanoelectronics” technology. NRI is made up of participants from the semiconductor industry, including GLOBALFOUNDRIES, IBM, Intel, Micron Technology and Texas Instruments.

“The NRI is a model for industry-driven consortia,” said NIST Director Patrick Gallagher. “It funds a highly leveraged, coordinated nanoelectronics research program centered at leading universities in partnership with federal and state government agencies. The innovation stemming from this NIST award will enable the United States to keep our current leadership in nanoelectronics that stimulates the economy and creates high-paying jobs.” NIST will provide $2.6 million to the effort for up to five years, matched by $870 thousand each year from NRI. The program funds research at university centers around the country that are working to develop the fundamental nanoscale technologies that will be needed in the future to replace the aging CMOS (“complementary metal–oxide–semiconductor”) transistor technologies at the heart of today’s state-of-the-art electronics. Over the past few decades, silicon-based CMOS circuits have relentlessly followed a path of getting smaller and more complex and powerful. However, the basic underlying transistor technology is approaching physical limits. “Continued progress by the electronics industry will require something very different. Future generations of electronics will be based on new devices and circuit architectures, operating on physical principles that cannot be exploited by conventional transistors,” said Tom Theis, director of the NRI. The new award is essentially the successor to an earlier five-year collaboration between NRI and NIST that also focused on the long-term goal of “developing the next logic switch.” The earlier program concentrated largely on the problem of developing the basic logic elements that are the building blocks of electronic devices. The new program will broaden the scope to consider novel circuit architectures and devices that combine logic with memory, analog and other functions to provide high “computational density.” The NRI initiative was launched by the Semiconductor Industry Association (SIA) in 2005. The NRI and the collaboration with NIST are managed by the Nanoelectronics Research Corporation (NERC), a special-purpose subsidiary of the Semiconductor Research Corporation (SRC). “The NRI seeks to insure that the United States remains the leader in cutting-edge semiconductor research and is home to the ‘nanoelectronics’ industry of the future,” said SRC President Larry Sumney. Since its inception, the NRI program has involved the research of nearly 500 students from more than 55 universities, resulting in 34 patent applications with seven patents granted and citations in more than 1,900 research publications. NRI currently supports four principle university-led research centers to pursue this work, including:

The award to NRI was the result of a competition announced by NIST last spring; see the March 20, 2012, news item “NIST Announces $2.6 Million in Funding for Novel Semiconductor Research” at www.nist.gov/public_affairs/tech-beat/tb20120320.cfm#semiconductors. Additional information on NRI is available at www.src.org/program/nri/. Media Contact: Chad Boutin, boutin@nist.gov, 301-975-4261

Slip Sliding Our Way: At the Nanoscale, Graphite Can Turn Friction Upside DownTheoretical Simulations of Friction Between Graphite and AFM Probe Credit: Smolyanitsky/NIST, Li/Tsinghua University If you ease up on a pencil, does it slide more easily? Sure. But maybe not if the tip is sharpened down to nanoscale dimensions. A team of researchers at the National Institute of Standards and Technology (NIST) has discovered that if graphite (the material in pencil "lead") is sticky enough, as measured by a nanoscale probe, it actually becomes harder to slide a tip across the material's surface as you decrease pressure—the exact opposite of our everyday experience. Technically, this leads to an effectively "negative coefficient of friction," something that has not been previously seen, according to team leader Rachel Cannara. Graphite, Cannara explains, is one of a special class of solids called "lamellar" materials, which are formed from stacks of two-dimensional sheets of atoms. The sheets are graphene, a single-atom-thick plane of carbon atoms that are arranged in a hexagonal pattern. Graphene has a number of exotic electrical and material properties that make it attractive for micro- and nanoelectromechanical systems with applications ranging from gas sensors and accelerometers to resonators and optical switches. Zhao Deng, a University of Maryland postdoctoral researcher at NIST's Center for Nanoscale Science and Technology, noted some odd data while experimenting on graphite with an atomic force microscope (AFM). Deng was measuring the friction forces on the nanoscale tip of an AFM tracking across the graphite as he modified the "stickiness" of the surface by allowing tiny amounts of oxygen to adsorb to the topmost graphene layer. Deng found that when the adhesive force between the graphene and the stylus became greater than the graphene layer's attraction to the graphite below, reducing the pressure on the stylus made it harder to drag the tip across the surface—a negative differential friction. Backed by theoretical simulations performed by collaborators from NIST and Tsinghua University in Beijing, Cannara's team found that, after the AFM tip has been pressed into the graphite surface, if the attractive force is high enough, the tip can pull a small localized region of the surface layer of graphene away from the bulk material, like raising a nanoscale bubble from the surface. Pushing that deformation around takes more work than sliding over a flat surface. Therefore, whenever the researchers pressed the AFM tip against the sticky graphite surface and then tried to pull the two apart, they measured an increase in friction force with a sensitivity in the tens of piconewtons. "Once we have a complete model describing how these graphene sheets deform under repeated loading and sliding at the nanoscale—which we're working on now—friction force microscopy may be the most direct way to measure the energy that binds these layered materials together. And, since it's nondestructive, the measurement can be performed on working devices," Cannara says. Understanding how the sheets interact with each other and with other parts of a device would help quantify the energy required to produce individual sheets from bulk material, assess device operation, and assist in formulating new structures based on layered materials, she says. * Z. Deng, A. Smolyanitsky, Q. Li, X.-Q. Feng and R. J. Cannara. Adhesion-dependent negative friction coefficient on chemically modified graphite at the nanoscale. Nature Materials. Published online: 14 October 2012 | doi:10.1038/nmat3452.Media Contact: Mark Esser, mark.esser@nist.gov, 301-975-8735

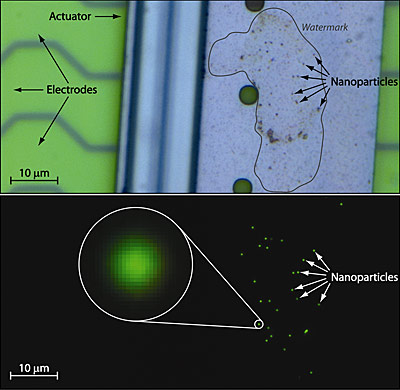

New Method Measures Movements of Tiny Devices-At Every StepMakers of minuscule moving machines—the kind being eyed for nanomanufacturing and assembly as well as other uses—do you know where your micro- and nanorobots really are?

Care to bet? A team of researchers at the National Institute of Standards and Technology (NIST) likely would likely prevail in such a hypothetical wager. On the basis of its surprising findings in an exacting study of the motions of an experimental microelectromechanical system (MEMS),* the team might even offer better-then-even odds. The group tracked, for the first time, the step-by-step motion of a standard type MEMS device called a "scratch drive actuator," a micromachine (120 micrometers wide, 50 micrometers long, and 1.5 micrometers thick) that drags itself over a surface by repeatedly flexing and relaxing a tiny hooked arm. Using a novel measurement method adapted from single molecule biophysics research, the researchers tracked and measured each of the device's 500 steps along a 20-micrometer path. They found that the incremental movements varied significantly, from just a few nanometers (nm) to almost 100 nm. This marked variability in step sizes was "unexpected," says Craig McGray, the first author of the paper. Typically, MEMS researchers have calculated an average step size, derived from the total distance traveled by a device over many operating cycles. The resulting average does not show the variability of the step sizes, while simple models of the behavior of the device have conveyed the impression that the devices move in uniform increments. Instead, McGray explains, "our method revealed very irregular step sizes, which had neither been observed previously nor predicted by established models of MEMS behavior." In their proof-of-concept experiment, the NIST team labeled the surface of a scratch drive actuator with fluorescent nanoparticles. Under a fluorescence microscope, the nanoparticles appeared as points of light in a starlike constellation. The position of each point of light was measured with exceedingly high accuracy, rendering the equivalent of a series of constellation maps and capturing the position and orientation of the device as it moved over a surface. Before and after every step of the device along the path, two images of the constellation were taken. The data were then crunched to determine the step-by-step increments and rotations, and the uncertainty in both values. With their innovative approach, the NIST team calculated both the size of each movement to within 1.85 nm, (smaller than the width of a strand of DNA) and the change in the device's orientation, also to an exceedingly low uncertainty. Rather than a straight line composed of evenly spaced points, the device took a somewhat ragged-edge route that curved slightly, with each step varying in length and orientation. In a subsequent test, the researchers measured a second scratch drive actuator made by the same manufacturer. The results also differed unexpectedly and significantly, as indicated by a 26.3 nm difference in average step sizes. Even as they work to refine their super-resolution fluorescence microscopy method, the team believes the approach can be broadly useful in the area of extremely small electromechanical systems. * C.D. McGray, S.M. Stavis, J. Giltinan, E. Eastman, S. Firebaugh, J. Piepmeier, J. Geist and M. Gaitan. MEMS kinematics by super-resolution fluorescence microscopy. Journal of Microelectromechanical Sytems. In press.Media Contact: Mark Bello, mark.bello@nist.gov, 301-975-3776

NIST Revises Software Patch Management Guide for Automated ProcessesThe National Institute of Standards and Technology (NIST) has published for public comment a revised draft of its guidance for managing computer patches to improve overall system security for large organizations. The previous version, issued as Creating a Patch and Vulnerability Management Program (NIST Special Publication 800-40) was written when such patching was done manually. The guide has been updated for the automated security systems now in use, such as those based on NIST's Security Content Automation Protocol. A "patch" is a piece of computer code that a software company writes and distributes to fix a problem found in one of its previously released programs. Many patches fix problems related to security—specifically, vulnerabilities in the programs that attackers can exploit. Hackers seek out these vulnerabilities to gain access to a computer and its information, which then can be used to gain access to other vulnerable computers and information. These compromised computers also can be used to attack other computers. To prevent these problems, patches need to be deployed to computer systems quickly to minimize the window of opportunity for attackers. But computer security professionals cannot necessarily just add the patch because of the disruption this might cause, such as inadvertently breaking other applications, causing computers to reboot during patch installation, or consuming all of a smartphone's monthly data allotment. Professionals need to follow a management process for identifying, acquiring, installing and verifying patches for products and systems. Guide to Enterprise Patch Management Technologies is designed to assist organizations in understanding the basics of patch management technologies. It explains the importance of patch management and examines inherent challenges in performing his function. The guide also provides an overview of enterprise patch management technologies and briefly covers metrics for measuring the technologies' effectiveness and for comparing the relative importance of patches. The guide provides recommendations that organizations should implement to improve the effectiveness and efficiencies of their enterprise management technologies. Organizations should:

The publication was created for security managers, engineers, administrators and others responsible for working with security patches. Auditors who need to assess the security of systems may also find the document valuable. The draft of Guide to Enterprise Patch Management Technologies, NIST Special Publication 800-40 Revision 3, may be downloaded from http://csrc.nist.gov/publications/drafts/800-40/draft-sp800-40rev3.pdf. Comments on the draft should be submitted by Friday, Oct. 19, 2012, to 800-40comments@nist.gov with the subject "SP 800-40 Comments." Media Contact: Evelyn Brown, evelyn.brown@nist.gov, 301-975-5661

New NIST Software Checks Performance of Biometrics Applications Against 2011 StandardA new software test suite developed at the National Institute of Standards and Technology (NIST) allows local and federal agencies and other users of the NIST's revised biometric standard to gain higher confidence that the correct biometric information can be shared between agencies accurately and rapidly. Biometric Conformance Test Software for Data Interchange Formats (BioCTS2012) includes a test suite designed to test implementations of the biometrics data standard ANSI/NIST-ITL 1-2011.* Published in November 2011, the standard provides a defined method for digitally encoding and storing biometric data so it can be shared by the various ID systems used by law enforcement, military and homeland security agencies. It vastly expands the type and amount of information that forensic scientists can share and is being adopted around the world to identify people. Data standards like ANSI/NIST-ITL 1-2011 only work when they're implemented correctly in software applications. NIST researchers developed the new conformance testing methodologies and test tools to support the user community, product developers and testing labs in forestalling problems. Conformance testing captures the technical description of a standard specification and measures whether an implementation faithfully executes the specification. BioCTS, for example, checks if the record of an iris image has the correct data, in the proper order, as called for by the standard, so that it can be sent to, received correctly by and filed accurately by any user from the Department of Homeland Security to a small police department. The conformance testing provides programmers, users and product purchasers with an increased level of confidence in product quality and increases the probability of successful interoperability. To support the conformance test suite, NIST scientists have developed two associated publications: Conformance Testing Methodology for ANSI/NIST-ITL 1-2011, Data Format for the Interchange of Fingerprint, Facial and Other Biometric Information Release 1.0 (Special Publication 500-295). Developed by NIST with help from experts from government and industry, it provides computer programmers with the background information and methodology they need to develop a conformance test tool for the ANSI/NIST standard. SP 500-295 documents over 1,200 test assertions implemented in BioCTS 2012, to test for a range of record types from fingerprint images to iris images. BioCTS 2012: Advanced Conformance Test Architectures and Test Suites for Biometric Data Interchange Formats and Biometric Information Records (NIST Interagency Report 7877) describes the implementation details of BioCTS 2012. NISTIR 7877 includes information on the conformance test architecture, for the ANSI/NIST–ITL 1-2011 standard and for conformance test suites designed to test implementations of biometric data interchange standards developed by Subcommittee 37– Biometrics of the ISO/IEC Joint Technical Committee 1–Information Technology and Biometric Information Records (BIRs) conforming to the Common Biometric Exchange Formats Framework (CBEFF). BioCTS currently covers several key types of biometric data, including, for example, fingerprints; facial images; scars, marks and tattoos; and iris images. NIST plans to extend the test tools to support additional biometric record types of the ANSI/NIST-ITL standard as well as other international biometric standards. Information regarding BioCTS 2012 testing architectures, code structure, and other software design details is provided in NISTIR 7877. "The goal of this project and future work is to support users, product developers and testing labs in a timely fashion by making the conformance test tools available as quickly as possible after new standards are developed," explains Project Manager Fernando Podio. The BioCTS software may be downloaded at www.nist.gov/itl/csd/biometrics/biocta_download.cfm. Conformance Testing Methodology for ANSI/NIST-ITL 1-2011, Data Format for the Interchange of Fingerprint, Facial and Other Biometric Information Release 1.0 (SP 500-295) is available at www.nist.gov/itl/csd/biometrics/ansi-nist.cfm. BioCTS 2012: Advanced Conformance Test Architectures and Test Suites for Biometric Data Interchange Formats and Biometric Information Record (NISTIR 7877) is available at http://csrc.nist.gov/groups/ST/BiomResCenter/CTA_BETA/APPROVED_NISTIR_7877.pdf. This work was supported in part by the Department of Homeland Security US-VISIT Program. *Data Format for the Interchange of Fingerprint, Facial & Other Biometric Information (ANSI/NIST-ITL 1-2011) is published in NIST SP 500-290, available at www.nist.gov/customcf/get_pdf.cfm?pub_id=910136.Media Contact: Evelyn Brown, evelyn.brown@nist.gov, 301-975-5661 |