For Consumers

On the Road Again: FDA's Mobile Laboratories

Get Consumer Updates by E-mail

Get Consumer Updates by E-mail

View the FDA mobile lab slide show »

View the FDA mobile lab slide show »

Printer-friendly PDF (273 KB) |

In August 2008, a convoy of trucks, trailers, and a motor home left Jefferson, Arkansas, for a nearly 2,000 mile road trip to the farmlands of the Salinas Valley in California.

The convoy is part of the Food and Drug Administration's (FDA) microbiology mobile laboratory—one of two mobile labs operated by the agency. Its mission in the Salinas Valley: to test and analyze fresh produce, picked right from the farms, for bacteria that have contaminated vegetables and sickened people in the past.

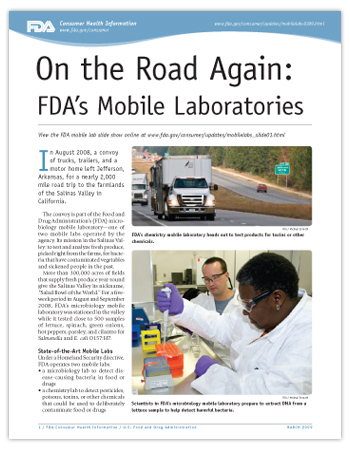

More than 300,000 acres of fields that supply fresh produce year-round give the Salinas Valley its nickname, "Salad Bowl of the World." For a five-week period in August and September 2008, FDA's microbiology mobile laboratory was stationed in the valley while it tested close to 500 samples of lettuce, spinach, green onions, hot peppers, parsley, and cilantro for Salmonella and E. coli O157:H7.

State-of-the-Art Mobile Labs

Under a Homeland Security directive, FDA operates two mobile labs:

- a microbiology lab to detect disease-causing bacteria in food or drugs

- a chemistry lab to detect pesticides, poisons, toxins, or other chemicals that could be used to deliberately contaminate food or drugs

Each mobile lab contains state-of-the-art instrumentation housed in modified 44-foot trailers, plus a 34-foot command center outfitted in a modified motor home. The fully functional, self-contained labs run on generators, carry their own water, and hold waste water in on-board tanks to prevent any release into the environment.

The command center serves as the sample entry and tracking point where samples are officially received and logged in before being transferred to the sample preparation trailer, and then to the analytical trailer for testing and analysis.

The microbiologists and chemists who work in the mobile labs are a "highly dedicated and experienced group of scientists," says Todd Bozicevich, director of the Laboratory Operations Branch in FDA's Division of Field Science within the Office of Regulatory Affairs. These specially trained analysts are not only skilled in setting up and tearing down the mobile lab components, says Bozicevich, but are also capable of maintaining the sensitive and sophisticated testing equipment, as well as performing general troubleshooting to keep the mobile labs operational.

Mobile Missions, Greater Reach

FDA's mobile labs are used for

- emergencies (such as an outbreak of illness)

- blitzes (short-term, intense testing of specific products at selected ports of entry)

- surveillance

- exercises to prepare for an emergency

In addition to the Salinas Valley, the mobile labs have been deployed to the Gulf of Mexico for hurricane relief and to several strategic locations along the U.S. borders with Canada and Mexico near major ports of entry.

The mobile labs complement FDA's 13 fixed-site labs, says Bozicevich. "The unique flexibility of the mobile labs gives us additional capability and surge capacity to perform testing on-site so we can reduce the elapsed time between sample collection and analysis. This allows us to identify problems more quickly."

The mobile labs are deployed based on a simple approach: perform screening analyses on samples to provide rapid results. If a mobile lab gets a positive test result from the sample screening, the sample is sent to a fixed-site lab for more extensive testing to confirm the mobile lab's results.

When not deployed, the mobile labs are stationed at FDA's Arkansas Regional Laboratory where the vehicles and the $3 million worth of instrumentation they contain are serviced and readied for their next mission.

Testing the Waters

The aftermath of Hurricanes Katrina and Rita spurred the first microbiology mobile lab deployment in 2005. The livelihood of the Gulf of Mexico fishing industry depends on the health of the beds of oysters, clams, and other mollusks in the gulf. None of that seafood could be sold until the gulf water was shown to be free of contamination by human waste. The multimillion-dollar gulf fishing industry was at a standstill until testing could be done.

With the Louisiana Department of Health and Hospitals' own laboratory sitting underwater, FDA deployed its microbiological mobile lab to provide resources and testing assistance to the state scientists. "Water samples must be tested within a specified number of hours of collection to get accurate results," says Bozicevich, "and the next nearest fixed-site testing lab was too far away." Working in the mobile lab, state and federal scientists tested over 400 water samples in a short time and determined the mollusk beds were not contaminated with disease-causing agents (pathogens); fresh seafood could start to be harvested and sold.

Surveillance in the Salinas Valley

The summer 2008 mobile lab deployment to the Salinas Valley was both a routine surveillance and a practice exercise for FDA. "In addition to testing fresh produce for bacteria, the exercise tested the lab's whole operation," says Thomas Sidebottom, special assistant to FDA's regional food and drug director, Pacific Region.

"Using the mobile labs to screen produce under normal conditions helps FDA be better prepared for a real emergency," Sidebottom says. "Our approach has now been tested and we've worked out the logistics to handle large volumes of samples."

In the Salinas Valley exercise, teams of consumer safety officers (CSOs) from FDA's San Francisco District and San Jose Resident Post gathered samples of fresh produce from growers' fields using special collection methods to avoid contamination of the produce (aseptic collection). They sealed the samples in sterile plastic bags and packed them into coolers to protect the integrity of the samples. Each day, the CSOs transported the samples to the mobile lab where they were checked in and then screened for E. coli O157:H7 and Salmonella.

FDA selected the Salinas Valley for testing based on "lessons learned" from the 2006 outbreak of illness from E. coli O157:H7 in fresh spinach grown in that same region. During that outbreak, FDA used fixed-site labs to test spinach samples. Samples had to be collected and then shipped overnight to the fixed-site laboratory. Using the mobile lab allows FDA to start testing samples within a few hours of their collection.

Increasing Testing Efficiency

Sample testing in any lab has certain time constraints. Two of the larger constraints are sample preparation and the paperwork involved with reporting results. "Preparing the samples for analysis is all about time, temperature, and technique," says Darlene Saudarg, a chemist for FDA's mobile labs. "You prepare a rinse of the sample, add enrichment broth to promote the growth of bacteria, incubate the enrichment broth, and then analyze a portion of the sample to see if any pathogens are present."

While the time it takes to analyze samples has been reduced, little can be done to speed up the enrichment process and bacteria growth rates. But FDA scientists working in the mobile lab have streamlined the operation by reducing the time involved with sample reporting. They replaced the previous, cumbersome paper system of documentation with bar codes for tracking samples and electronic worksheets for entering and sharing test results. These steps served to dramatically decrease the time per sample and increase the number of samples analyzed (throughput) while still maintaining the chain-of-custody and integrity of the analysis.

Partnering to Protect the Food Supply

The Salinas Valley mobile lab operation ran smoothly because of the collaboration and support of many partners, including

- federal agencies, such as the Agricultural Research Station of the U.S. Department of Agriculture (USDA), which permitted FDA to park its lab on USDA property

- state and county public health, agriculture, and regulatory offices

- food growers, producers, and industry associations

Two organizations representing the produce industry recruited growers to allow FDA access to the fields for pre-harvest sample collection. "FDA gave us a list of crops of concern, and then we made the phone calls to growers," says Jim Bogart, president of the Grower-Shipper Association. "We didn't have to twist a lot of arms. When we presented our members with the situation and the benefits, the response was real good."

Bob Whitaker, chief science officer at the Produce Marketing Association, says industry favors testing samples before harvest versus testing a product pulled off a store shelf or out of a shipping container. "If you pick a needle out of the haystack and find something, you're going to have to track it down and recall it," he says. "If you find a problem prior to harvesting, it never will be harvested, so there is no threat to public health."

FDA and the growers agreed that if a sample tested positive, FDA would share that information immediately with the farm and the industry associations so they could track down the source of the contamination. The mobile lab, in conjunction with FDA's district lab, did confirm a positive sample for Salmonella during this deployment.

The labs notified the farm and the industry associations who ensured that the produce was not harvested. These safeguards prevented the produce in question from entering the food chain and also prevented the potential contamination of equipment and other produce. As a result, none of the produce tested by the microbiological mobile lab has been linked to any confirmed illnesses.

Preventing problems before a product is shipped to market is a key component of FDA's Food Protection Plan, a strategy for protecting the nation's food supply by focusing on safety along the entire production chain—from farm to table. FDA's mobile labs play a vital role in enhancing the level of food protection for the American consumer.

This article appears on FDA's Consumer Updates page, which features the latest on all FDA-regulated products.

Date Posted: March 30, 2009