#LabChat Recap: Innovations Driving More Efficient Vehicles

The #LabChat on Dec. 13 sparked an engaging discussion about technologies that are improving vehicle fuel economy. Three researchers answered questions about advanced combustion, lightweighting and hybridization. Here is an overview of some of the conversations.

Storified by Energy Department ·

Fri, Dec 21 2012 08:19:22

We kicked off the #LabChat with introductions from all the

researchers. Each researcher focuses on a different vehicle

technology that is expected to make great strides in improving vehicle

mileage.

Welcome to #LabChat: Innovations Driving More Efficient Vehicles

Energy Department technology manager Gurpreet Singh leads

the Advanced Combustion Engine Technologies team, which focuses on improving

combustion engines and emissions control technologies that will make vehicles

drive farther on less fuel.

Dean Paxton is a Pacific Northwest National Laboratory

researcher who focuses on advances in lightweight vehicle materials. As Paxton

points out below, this is important because lighter vehicles will help reduce

the amount of fuel vehicles use.

@argonne - my research area is lightweight materials, a 10% decrease in vehicle wt will increase fuel economy by 6-8% #labchat

Argonne

National Laboratory researcher Eric Rask explores new technological

developments in electric and other advanced vehicles.

Before we get into the specific technologies that are

improving vehicle fuel economy, it is important to understand how vehicles have

changed over time as well as what the Energy Department's National Laboratories

are doing to make vehicles more efficient today than the ones in the

past. This video from Argonne National Lab provides a nice overview of why

vehicle advancements are important.

One of the first questions focused on new information

technology developments that could help consumers save money on fuel

costs.

IT increases fuel efficiency by leveraging smart-phones to find optimal route. #Opendata from cities also helps avoid traffic #LabChat

IT reduces pollution. Mechanics use on-board diagnostics to measure/control vehicle emissions on all US cars since 1996 #LabChat

#Opendata from vehicles, like OBD, tells owners when preventative maintenance is needed, which saves fuel #LabChat http://go.usa.gov/gmmG

While we shared a handful of examples on ways open data can

help improve vehicle fuel efficiency, we are looking for innovators to share

their best business plans, app ideas and product designs that use open vehicle

data to help vehicle owners save fuel, save money and stay safe as part of the Apps for

Vehicles Challenge.

Many of the people joining #LabChat had questions about the

potential of incorporating lightweight materials in vehicles. But did you know

that many of the cars on the road today already use some lightweight

materials?

@ENERGY - All cars made today use all or some LW materials, such as adv high-strength steel, aluminum, magnesium, & composites #labchat

However, we face many challenges in replacing steel alloys

with advanced, lightweight materials. Lightweight materials are more

complicated to join to other materials, more difficult to model, more

challenging to recycle than conventional iron and steel alloys, and of course,

more expensive.

@frannywhite @ENERGY- will depend on the matl, but LWM are more expensive to make into parts than heavier materials will replace #labchat

@frannywhite @ENERGY-typical will be $3-$10 more for LWM for every lb of heavier material saved, but also depends on gas prices #labchat

While lightweight materials might be more expensive, they do

make fuel-efficient alternative power systems -- like hybrids, plug-in hybrids

and all-electric vehicles -- possible. Lighter

materials also allow cars to carry advanced emission control systems,

safety devices and electronic systems without increasing their weight.

@sciwriter - lw materials that reduce wt of vehicles can make many alternative propulsion/power systems more viable #labchat

When it comes to hybridization, our audience skipped the easy questions and went straight to the hard ones. But

for everyone else, hybridization is when a vehicle has both an internal

combustion engine and an electric motor that uses energy stored in a battery.

Hybrids are some of the most efficient vehicles on the road because the second

power source (the battery) is used instead of fuel, helping increase a

vehicle's miles per gallon.

Now that we know the basics of hybridization, we can explore

the technology in more detail. What is microhybridization and what

are the cost considerations?

@sciencewriter, @arthurhcyip: I consider micro-hybrid primarily engine stop-start. We'll see about the economics. Available soon. #LabChat

As Rask explains, micro hybrids -- also called stop-start

hybrids -- include a small electric motor that allows the vehicle to

shut off the engine when the vehicle stops, such as at traffic lights or

in stop-and-go traffic.

When it comes to cost, micro hybrids could be less expensive

than mild or full hybrids because they have a smaller battery. But micro

hybrids also have lower fuel economy than mild or full hybrids because micro

hybrids can't use only the electricity stored in the battery to power the

vehicle.

With full

hybrids -- which have larger batteries and electric motors that enable

them to drive using just the electric power for short distances -- there are a

couple different ways to combine the power from the electric motor and the

combustion engine. Parallel hybrids use both the electric motor and the engine

to turn the wheels of the vehicle, while series hybrids only use the electric

motor to move the wheels. As Rask points out, the majority of hybrids on the

market combine both parallel and series technology.

.@TScott0: The majority of current hybrids are actually power-split, which offers both series and parallel functionality. #LabChat

Power-split technology works by hooking

the combustion engine, generator and electric motor together. This allows

the vehicle to operate like a parallel hybrid -- the electric motor, combustion

engine or both can power the vehicle -- or a series hybrid -- the combustion

engine can be used to independently power the vehicle's accessories.

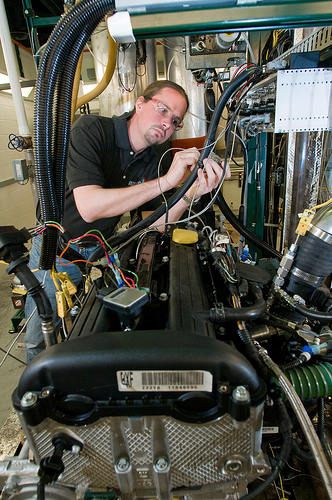

The third focus of the #LabChat was on advanced

combustion -- which is finding new ways to combine and ignite air

and fuel more efficiently. This picture shows an Argonne researcher getting

real-time feedback on advanced combustion technologies.

With technology improvements, there is always a question

about the return on investment (ROI), and with vehicle technology, it is no

different.

Depends on the tech and efficiency improvement. For ex, in heavy duty engine tech research, we have seen ROI greater than 50:1 #labchat

When it comes to the investment in new commercial engine

technology, Energy Department-sponsored research and development has helped

engine manufactures improve diesel engine efficiency by 4-5

percent since 2002, saving more than 2.4 billion gallons of

diesel fuel.

@PNNLNews #LabChat what's the future of variable displacement engines with efficiency?

Another way to save fuel is to have a smaller engine in the

vehicle. Or you can have an engine that sometimes acts like a smaller engine by shutting off some of the cylinders when not in use -- this is

called cylinder

deactivation or cylinder cut-out. Cylinder deactivation is not a

new technology -- the first experiments with cylinder deactivation happened

during World War II and later the technology was included in a few vehicle

models in the second half of the 20th century -- and automakers are increasingly

interested in this technology to meet fuel economy goals.

We expect to see more engines w/variable displacement (cylinder cut-out) in the future to improve fuel economy in urban driving #labchat

Cylinder deactivation allows an 8-cylinder engine to act as if

it is a 6-cylinder engine to improve fuel economy. During normal usage -- like

accelerating and going uphill -- the engine uses all of its cylinders. But

during low-load conditions -- like cruising on the highway and low-speed urban

driving -- some of the engine's cylinders turn off. This technology isn't just

for gasoline-powered engines. As Singh suggests, it can also be incorporated

with diesel technology.

Yes! RT @MPGomatic: @ENERGY Wondering: could cylinder deactivation be used with clean diesel applications? #labchat

@ENERGY - in LW mtls, many mtls have been demonstrated to meet functional reqts for automotive, but the mtl costs are too high #labchat

Getting to a reasonable payback period for customer acceptance is a challenge for advanced technologies #labchat

![]()