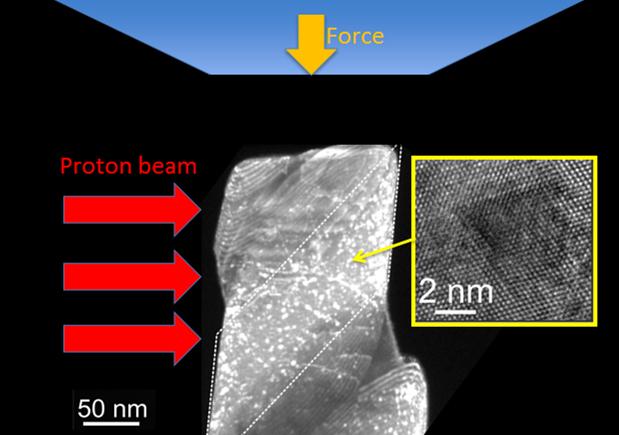

Scientists conducted compression tests of copper specimens irradiated with high-energy protons, designed to model how damage from radiation affects the mechanical properties of copper. By using a specialized in situ mechanical testing device in a transmission electron microscope at the National Center for Electron Microscopy, the team could examine — with nanoscale resolution — the localized nature of this deformation. | Courtesy of Lawrence Berkeley National Laboratory

Tests are often stress-inducing. But when it comes to stress-testing irradiated materials, sometimes, those stressful tests can actually make for safer situations . . . and perhaps make everyone a bit less stressed.

That’s the case for researchers at the Energy Department's Office of Science Lawrence Berkeley Laboratory who, with their counterparts at the University of California Berkeley and Los Alamos National Laboratory, have devised a new way to determine the strength of materials: a method that may be used to test tiny (“nano”) materials, but also has the potential to provide insights on the properties of materials exposed to the extreme environments in nuclear reactors.

Nuclear plants do more than supply power (about 20 percent of our nation’s electricity); they also produce the radioisotopes used in medicine for detecting and treating many diseases. But the energetic particles produced by power plants places stress on materials. That can be a problem. Testing such materials can be stressful too –- especially if they’ve become radioactive.

That’s where Berkeley scientists and their colleagues came in. They discovered a new, and possibly better, way to test the stress put on materials exposed to radiation (irradiated). While conventional stress tests require a significant amount of material, the new test requires an infinitesimal amount; a specimen as small as 400 nanometers in diameter (by comparison, a human hair is approximately 80,000 nanometers wide). Moreover, those tiny samples can be used to show the strength of the substance as a whole.

The researchers, working out of the National Center for Electron Microscopy, tested their new testing technique on a sample of copper. First they exposed it to proton irradiation (tiny, high-energy particles with a positive charge). Then they compressed the sample and scanned it for changes. Atoms in metals tend to stack up in relatively regular arrangements of stacked layers that build up into lattices. The scientists discovered signs of stress in layers a few atoms deep.

The test gives scientists a better understanding of how radiation stresses a material, of the specific changes in tiny groups of atoms that could eventually cause a material to fail. That understanding, in turn, could lead to the discovery (or even design) of materials that might better withstand radiation stresses.

The tests aren’t perfect. For example, the form of radiation that Berkeley researchers used in their tests does not perfectly mirror the exposures or stresses that materials experience inside nuclear facilities.

That said, the Berkeley test is a sign of progress, showing new insights into the stress placed on irradiated materials. It may eventually serve as a useful tool in making our energy cleaner and our power sources safer.

For more information about research at Lawrence Berkeley Laboratory, please go to: http://www.lbl.gov/. And for more information on Energy Department's Office of Science, please go to: http://science.energy.gov/.