| * |

|

Membranes for Clean Water

Summary:The goal of this project is to develop quantitative

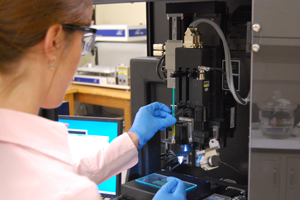

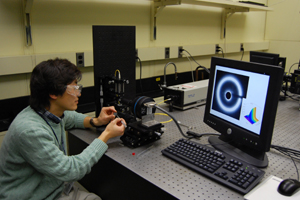

Highlights: Soft Materials Buckle Up for Measurement New Test Measures Key Properties of Polymer Thin Films and Membranes Description:Membrane-based water purification technologies, such as reverse osmosis (RO), forward osmosis (FO) and nanofiltration (NF), rely on a very thin active layer traditionally comprised of a interfacially polymerized polyamide. Since these membranes are formed by diffusion of reactants through an actively-forming, highly crosslinked film, the resulting membrane structure is ill-defined and highly heterogeneous, making accurate measurements of the membrane structure/property relationships difficult. To this end, we are developing model membranes with defined structure to facilitate the development of measurement platforms for interrogating the fundamental aspects of transport in thin film composite (TFC) membranes.

Moreover, commercial TFC membranes are known to undergo chemical degradation due to the introduction of chlorine to prevent membrane fouling. We are developing measurement techniques to quantify the effect of chlorine degradation on the mechanical properties of the active layer in these types of membranes. Our approach combines surface wrinkling and thin film cracking to probe the elastic modulus, tensile strength and fracture strain of the active layer as a function of chlorine exposure. We relate our results to structural changes in the membrane due to disruption of internal hydrogen bonding upon chlorination.

Selected Publications

|

Start Date:October 1, 2010End Date:ongoingLead Organizational Unit:mmlStaff:Christopher Stafford - Project Leader Associated Products:Project Summary (PDF) Contact

Christopher M. Stafford |