| * |

|

Hydrogen Pipeline Safety

Summary:Our goal is to establish the codes and standards necessary to ensure safe distribution of hydrogen fuels. The future hydrogen economy will depend on efficient transport of fuel across the U.S., preferably using our existing network of oil and gas pipelines where hydrogen degradation is likely to occur. By establishing unique test facilities and standard test procedures, we will provide pipeline operators with critical data on the durability of pipeline materials in high-pressure gaseous hydrogen environments.

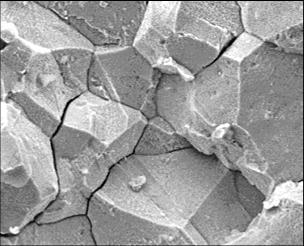

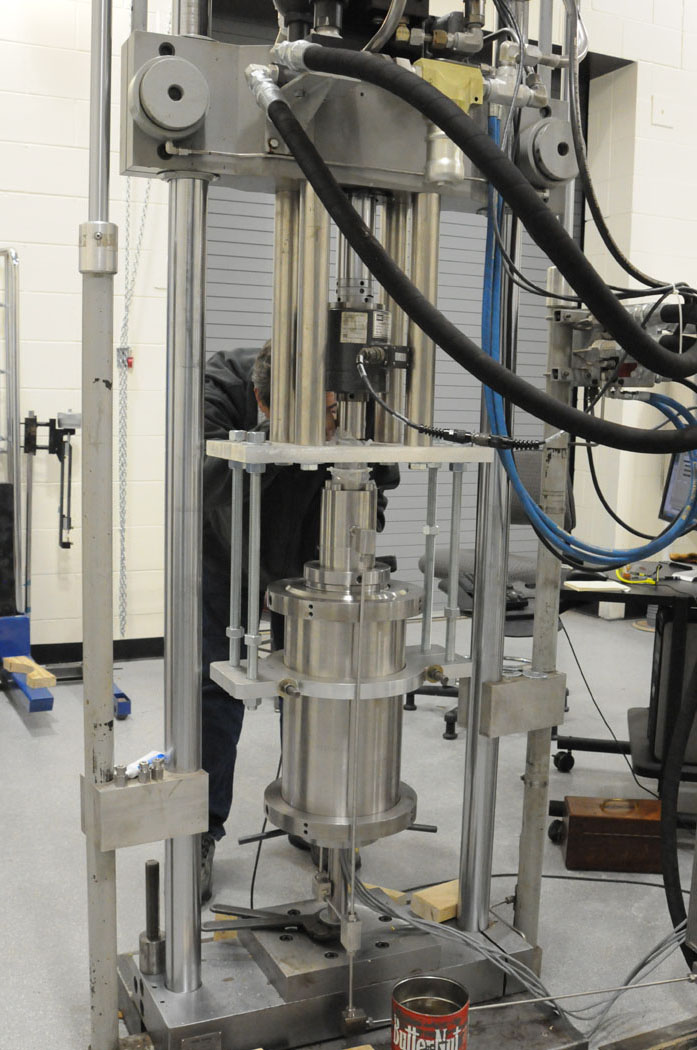

Embrittlement of steel microstructure due to exposure to hydrogen. Description:The Materials Reliability Division has established a unique, state-of-the-art high-pressure gaseous hydrogen test facility dedicated to measuring the mechanical properties of metallic and composite structural materials proposed for use for the transport and storage of hydrogen gas. The facility has the capability of testing at hydrogen pressures up to 138 MPa. This laboratory was designed first and foremost with safety in mind. Safety features include explosion-proof (EP) switches, EP outlets, EP lighting, high air exchange rate, regional lightning detection system, and a fail-safe pressurized hydrogen gas cut-off system. The control room is remote from the testing lab, enhancing the personnel safety aspect of the facility.

In FY10 fatigue testing of existing and new pipeline steels that are proposed for hydrogen service will be conducted. One load frame is capable of fatigue loading up to 100 kN, and our test chamber can provide pressures of up to 138 MPa for testing in gaseous atmospheres. We have recently added a 250 kN fatigue machine and we will construct a new test chamber that will accommodate 10 fatigue specimens that can be simultaneously tested. This will provide critical design data in one-tenth of the normally expected time.

X52 tensile testing in both hydrogen and air. The two images on the right show the fracture surface of a specimen tested in air on top, and in hydrogen on bottom. |

Start Date:October 1, 2006End Date:ongoingLead Organizational Unit:mmlRelated Programs and Projects:Associated Products:Project Summary (PDF) Contact

Andy Slifka |